Have you ever wondered what happens to all the rubber that gets thrown away after its useful life? It’s hard not to notice rubber products all around us, from the soles of our shoes to the tires on our cars. However, unlike many other materials, recycling rubber is not as straightforward. This once stretchy and bouncy material has a stubborn side that makes it quite the challenge for recycling programs.

Over time, the use of rubber in various applications has increased, and so has the production of rubber waste. Unfortunately, only a tiny fraction of that waste material is recycled every year, which begs the question: why isn’t rubber recycled more?

There are several reasons why rubber is not easily recycled, and different types of rubber present different challenges. For example, natural rubber cannot be recycled in the same way synthetic rubber can. Additionally, additives, fillers, and metal can make the process of recycling rubber more expensive and time-consuming.

But don’t lose hope just yet; there are some fascinating alternative uses for recycled rubber that have pushed inventive recycling methods in recent years. In this post, we will delve into why recycling rubber is difficult and explore some innovative ways that recycled rubber is being used. So let’s get rolling.

What is Rubber?

Contents

Rubber is a versatile and durable material that has been utilized in various industries for centuries. This elastic substance can be stretched and molded into different shapes without breaking or losing its properties. The primary source of rubber is the sap of rubber trees in tropical regions. The sap is collected by making a small incision in the bark of the tree, which is then processed to remove impurities and make it suitable for use.

Natural rubber is biodegradable, which means it can decay over time when exposed to natural elements such as air, sunlight, and water. On the other hand, synthetic rubber, which is made from petroleum-based products, is not biodegradable and can take hundreds of years to decompose.

Rubber has many beneficial properties that make it useful in various industries, including automotive, construction, and medical. It is resistant to heat, water, chemicals, and electricity while also being able to absorb shock and vibration. Rubber is used to make tires, hoses, belts, gaskets, seals, gloves, and many other products.

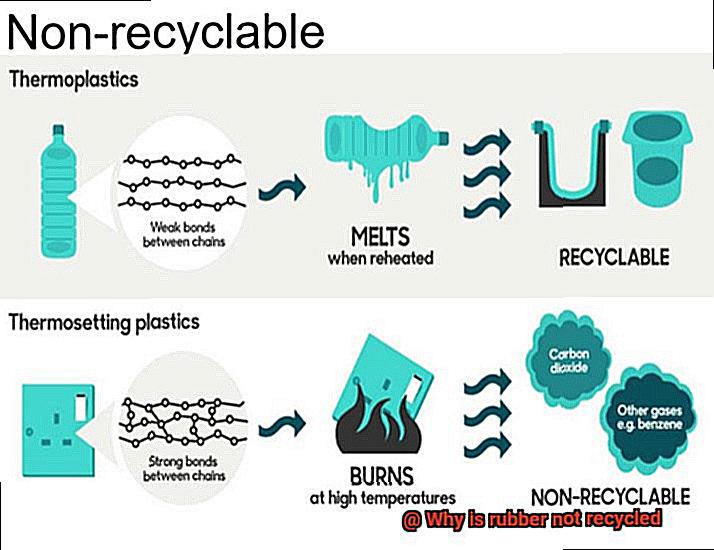

Despite its numerous benefits, rubber is not easily recyclable. Most recycling facilities do not have the equipment or technology to process rubber effectively. The components that make up rubber products such as carbon black and sulfur make it challenging to recycle them. Additionally, recycled rubber products may not meet the same performance standards as new rubber products.

There are several reasons why rubber is not commonly recycled. One reason is due to its complex composition that consists of various chemicals and additives that make it difficult to recycle. The process of recycling rubber involves breaking down the material into its constituent parts, which can be challenging due to its molecular structure. Another reason is due to the high cost of recycling as it requires specialized equipment and expertise that can be expensive.

The lack of infrastructure and regulations for rubber recycling also contributes to its low recycling rate. There are no standard processes or regulations for recycling rubber. This means there are few incentives for businesses to invest in rubber recycling, leading to a low demand for recycled rubber products.

Despite these challenges, innovative solutions are being developed to recycle rubber effectively while minimizing environmental impact. New technologies and equipment are being developed to improve the recycling process and create new markets for recycled rubber products.

Challenges of Recycling Rubber

Rubber, a material that has been utilized for centuries due to its versatility and durability, presents a unique set of challenges when it comes to recycling. Unlike paper, plastic, or glass, rubber is a complex material made up of various chemicals and compounds. This complexity makes it difficult to recycle effectively without losing its valuable properties.

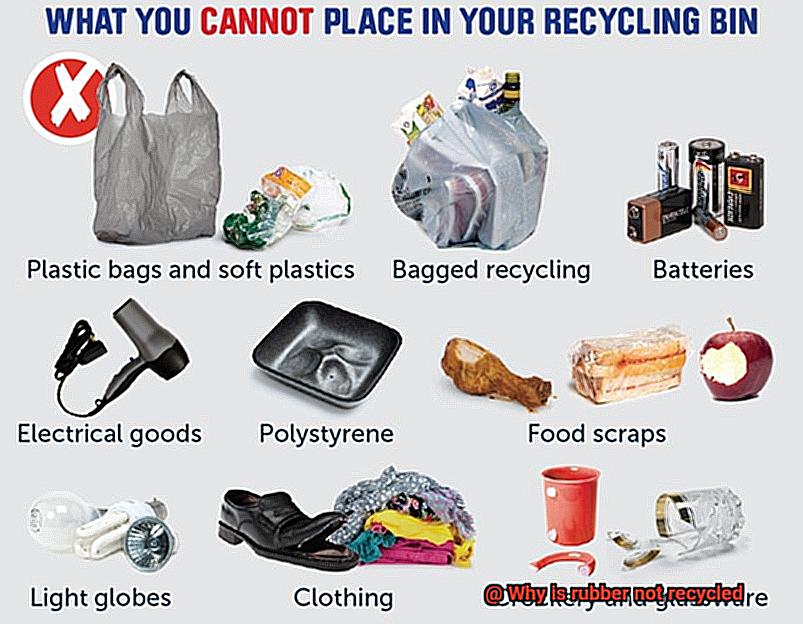

On top of this complexity, rubber is often contaminated with other materials such as dirt, metal, and non-rubber materials. This contamination can make processing the material difficult and lead to poor-quality recycled rubber products.

Moreover, the demand for recycled rubber is relatively low compared to other recycled materials like plastic or paper. This lack of demand means that there are fewer incentives for companies to invest in the technology and infrastructure necessary for effective rubber recycling.

Another significant challenge is the cost of recycling rubber. Specialized equipment and processes are required to recycle rubber effectively, making it more expensive than recycling other materials. This cost can make it difficult for companies to justify investing in rubber recycling programs.

Despite these challenges, progress is being made in the field of rubber recycling. Innovative solutions such as mechanical grinding, cryogenic grinding, and devulcanization are being developed to improve the recycling process and create new markets for recycled rubber products.

These advancements are driven by increased demand for sustainable products and a growing awareness of the need to reduce waste. By developing more efficient processes for recycling rubber, we can help create a more sustainable future while also reducing our impact on the environment.

The Cost of Recycling Rubber

The process of recycling rubber involves multiple steps, including collection, sorting, shredding, and processing. Each of these steps requires time, labor, and resources, which add up to a considerable cost. But why is it so expensive? Let’s dive in.

One of the most prominent challenges in recycling rubber is the high cost of transportation. Rubber products are often bulky and heavy, which makes it costly to transport them from collection points to processing facilities. Additionally, the cost of sorting and separating different types of rubber can be quite high. This is because rubber can be contaminated with other materials like textiles, metal, or plastic.

Apart from transportation and sorting, another costly aspect of recycling rubber is the need for specialized equipment and machinery. Different types of rubber require specific processing methods, such as cryogenic grinding or devulcanization, which require specialized equipment that can be expensive to operate and maintain.

Finally, the limited market for recycled rubber products makes it challenging for recyclers to generate revenue from their efforts. Although there are some applications for recycled rubber products, such as in playground surfaces or asphalt paving, the demand for these products may not be enough to justify the cost of recycling.

So what can we do to address these challenges? One solution is to invest in new technologies that streamline the recycling process and reduce costs. For example, new sorting technologies can separate different types of rubber more efficiently, while new processing methods can reduce the need for specialized equipment.

Another solution is to increase demand for recycled rubber products by promoting their benefits and creating new applications. Recycled rubber has excellent insulation properties and can be used in a variety of products like shoe soles or even building materials.

Lack of Infrastructure and Regulations for Rubber Recycling

Rubber is a highly versatile material that is widely used across different industries. However, despite its widespread use, rubber recycling remains a challenge. One of the most significant obstacles to successful rubber recycling is the lack of infrastructure and regulations.

Unlike other materials such as plastic or glass, rubber recycling requires specialized equipment and facilities that are not readily available in many parts of the world. The high cost of establishing such facilities can be prohibitive, especially for small-scale recycling operations. Unfortunately, this results in rubber waste being sent to landfills instead of being recycled.

Moreover, the lack of standardized regulations for rubber recycling poses a significant problem. Without proper guidelines or regulations for collecting, sorting, processing, and disposing of rubber waste, it becomes difficult to ensure that recycled rubber is safe for use in new products. This lack of regulation also makes it challenging to monitor the activities of rubber recyclers and prevent illegal dumping.

Additionally, some countries have cultural barriers to rubber recycling. For instance, in many African countries, old tires are often used as fuel for cooking or heating instead of being recycled. While this practice may seem practical in the short term, it leads to air pollution and prevents tires from being recycled into new products.

To address these challenges, governments and industry stakeholders need to work together to establish standardized regulations and invest in the necessary infrastructure to support sustainable rubber recycling practices. By doing so, we can ensure that recycled rubber can be safely used in new products while minimizing environmental pollution.

Innovative Solutions to Reduce Waste and Promote Sustainability

The world is facing severe effects of the climate crisis, and innovative solutions to reduce waste and promote sustainability are more essential than ever. The rubber industry, in particular, is plagued with one of the most significant waste problems due to the piling up of used tires and other rubber products in landfills. Unfortunately, rubber is not an easily recyclable material, making it a significant challenge for sustainable practices.

The inherent properties of rubber make it difficult to break down, primarily due to the long chains of molecules that make up its polymer structure. Although rubber recycling involves devulcanization, where the chemical bonds holding the polymer chains are broken apart, the process requires a lot of energy and can be expensive. Moreover, the resulting material is often of lower quality than virgin rubber.

Despite the challenges, there are innovative solutions being developed to tackle this problem. One such solution is exploring new methods of devulcanization that are more energy-efficient and cost-effective. By investing in research and development, we can achieve a more feasible rubber recycling process in the future.

Another innovative solution involves repurposing used rubber products in new ways. For instance, old tires can be transformed into playground surfaces or used as filler material in asphalt. These initiatives create new opportunities for sustainable practices while reducing waste.

Although rubber recycling remains a challenging issue, collaborative efforts from governments and industry stakeholders can bring about standardized regulations and necessary infrastructure to ensure sustainable practices that minimize environmental pollution. By continuing to invest in research and development, we can help reduce waste and promote sustainability in the rubber industry and beyond.

R7N5a476DKQ” >

Conclusion

To sum up, recycling rubber is a complex task that presents unique challenges. Its intricate chemical makeup, along with the presence of additives, fillers, and metal, makes it difficult to recycle effectively. Furthermore, the absence of proper infrastructure and regulations for rubber recycling exacerbates the problem.

However, we can take heart in the fact that innovative solutions are being developed to overcome these challenges and promote sustainable practices in the rubber industry. New technologies and equipment are emerging to improve the recycling process while reducing costs. For instance, advanced sorting technologies can separate different types of rubber more efficiently. Additionally, new processing methods can reduce the need for specialized equipment.

Furthermore, repurposing used rubber products in new ways creates opportunities for sustainable practices while reducing waste. It’s worth noting that collaborative efforts from governments and industry stakeholders can bring about standardized regulations and necessary infrastructure to ensure sustainable practices that minimize environmental pollution.

By continuing to invest in research and development, we can help reduce waste and promote sustainability in not only the rubber industry but also other sectors. Although there are still challenges ahead, we should remain optimistic about the future of rubber recycling.